a)

To determine: The standard time for the operation.

Introduction: The amount of the dependency on human effort by an organization in terms of achieving its goals is given by the work design. It is directly linked to the productivity of an organization where good work design helps in achieving high productivity.

a)

Answer to Problem 10P

Explanation of Solution

Given information:

| Element | Performance rating | Observations (minutes per cycles) | Allowance | |||||

| 1 | 2 | 3 | 4 | 5 | 6 | |||

| 1 | 1.1 | 1.2 | 1.17 | 1.16 | 1.22 | 1.24 | 1.15 | 0.15 |

| 2 | 1.15 | 0.83 | 0.87 | 0.78 | 0.82 | 0.85 | 0 | 0.15 |

| 3 | 1.05 | 0.58 | 0.53 | 0.52 | 0.59 | 0.6 | 0.54 | 0.15 |

Formula:

Calculation of standard time of operation:

| Element | Performance rating | Observations (minutes per cycles) | Allowance | Observed time | Normal time | Afjob | Standard time | |||||

| 1 | 2 | 3 | 4 | 5 | 6 | |||||||

| 1 | 1.1 | 1.2 | 1.17 | 1.16 | 1.22 | 1.24 | 1.15 | 0.15 | 1.198 | 1.317 | 1.15 | 1.52 |

| 2 | 1.15 | 0.83 | 0.87 | 0.78 | 0.82 | 0.85 | 0 | 0.15 | 0.83 | 0.954 | 1.15 | 1.10 |

| 3 | 1.05 | 0.58 | 0.53 | 0.52 | 0.59 | 0.6 | 0.54 | 0.15 | 0.564 | 0.592 | 1.15 | 0.68 |

| Standard time for operation | 3.29 | |||||||||||

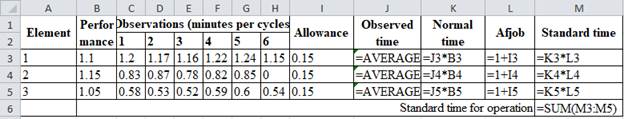

Excel Worksheet:

Element 1:

Observed time is calculated by taking mean for the 1.2, 1.17, 1.16, 1.22, 1.24 and 1.15 which gives 1.198.

Normal time is calculated by multiplying observed timing, 1.198 and performance rating, 1.1 which yields 1.317 minutes.

Allowance factor is calculated by adding 1 with the allowance factor 0.15 to give 1.15.

Standard time for element 1 is calculated by multiplying normal time of 1.317 minutes with allowance factor of 1.15 which gives 1.52 minutes.

Same process applies for element 2 and 3 which yields the standard times as 1.10 and 0.68. The standard time for operation is obtained by adding 1.52, 1.10 and 1.68 minutes which gives 3.29 minutes.

Hence, the standard time for the operation is 3.29 minutes.

b)

To determine: The number of observations for element 2.

Introduction: The amount of the dependency on human effort by an organization in terms of achieving its goals is given by the work design. It is directly linked to the productivity of an organization where good work design helps in achieving high productivity.

b)

Answer to Problem 10P

Explanation of Solution

Given information:

| Element | Performance rating | Observations (minutes per cycles) | Allowance | |||||

| 1 | 2 | 3 | 4 | 5 | 6 | |||

| 1 | 1.1 | 1.2 | 1.17 | 1.16 | 1.22 | 1.24 | 1.15 | 0.15 |

| 2 | 1.15 | 0.83 | 0.87 | 0.78 | 0.82 | 0.85 | 0 | 0.15 |

| 3 | 1.05 | 0.58 | 0.53 | 0.52 | 0.59 | 0.6 | 0.54 | 0.15 |

Confidence= 95.5%

1% of true value

Formula:

Calculation of number of observations for element A:

In the above formula the sample standard deviation is calculated by,

Calculation of standard deviation:

| Element 2 | Differences | Square of differences | Standard deviation |

| 0.83 | 0 | 0 | 0.0339 |

| 0.87 | 0.04 | 0.0016 | |

| 0.78 | -0.05 | 0.0025 | |

| 0.82 | -0.01 | 0.0001 | |

| 0.85 | 0.02 | 0.0004 | |

| Mean=0.83 | SSQ=0.0046 |

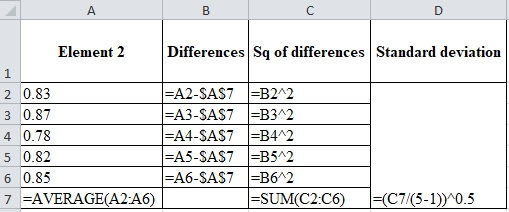

Excel worksheet:

Z value for confidence interval of 95.5% is 2.00.

The confidence interval

- Using z = 2.00:

The number of observations from the standard z table for confidence level of 95.5% is calculated by dividing the product of 2.00 and 0.0339 with product of 0.01 and 0.83 and squaring the resultant which gives 66.7272.

- Using z = 2.01:

The number of observations from the standard z table for confidence level of 95.5% is calculated by dividing the product of 2.01 and 0.0339 with product of 0.01 and 0.83 and squaring the resultant which gives 67.3962.

Hence, the number of observation is 68.

c)

To determine: The number of observations needed to estimate the mean time for element 2 within 0.01 minute of its true value.

Introduction: The amount of the dependency on human effort by an organization in terms of achieving its goals is given by the work design. It is directly linked to the productivity of an organization where good work design helps in achieving high productivity.

c)

Answer to Problem 10P

Explanation of Solution

Given information:

| Element | Performance rating | Observations (minutes per cycles) | Allowance | |||||

| 1 | 2 | 3 | 4 | 5 | 6 | |||

| 1 | 1.1 | 1.2 | 1.17 | 1.16 | 1.22 | 1.24 | 1.15 | 0.15 |

| 2 | 1.15 | 0.83 | 0.87 | 0.78 | 0.82 | 0.85 | 0 | 0.15 |

| 3 | 1.05 | 0.58 | 0.53 | 0.52 | 0.59 | 0.6 | 0.54 | 0.15 |

Confidence= 95.5%

0.10 minute of actual value.

Formula:

Calculation of number of observations for element C:

In the above formula the sample standard deviation is calculated by,

Z value for confidence interval of 95.5% is 2.00.

The confidence interval

- Using z = 2.00:

The number of observations from the standard z table for confidence level of 95.5 is calculated by dividing the product of 2.00 and 0.0339 with 0.01 and squaring the resultant which gives 45.9684.

- Using z = 2.00:

The number of observations from the standard z table for confidence level of 95.5 is calculated by dividing the product of 2.01 and 0.0339 with 0.01 and squaring the resultant which gives 46.4292.

Hence, the number of observations needed to estimate the mean time for element 2 within 0.01 minute of its true value is 46.

Want to see more full solutions like this?

Chapter 7 Solutions

Operations Management (Comp. Instructor's Edition)

- 5. The manager of Asombrado Bounty Office, Charles Badillo, estimates his employees are idle 25%of the time. With that problem, how many work samples are needed to consider within 3%accuracy and have 95.45% confidence level. 6. At ASP Micro Manufacturing, Inc. workers press semiconductor into predrilled slots on printed-circuit boards. Determine the normal time of the operation in seconds. The elemental motions for normal time used by the company are as follows:• Reach 6 inches for semiconductors 10.5 TMU• Grasp the semiconductors 8.0 TMU• Move semiconductor to printed-circuit board 9.5 TMU• Position semiconductor 20.1 TMU• Press semiconductor into slots 20.3 TMU• Move board aside 15.8 TMU 7. The semiconductor used in Costin Calculator has 5 components with the consistency of 90%, 95%,98%, 90%, and 99%, respectively. How reliable is one product of calculator?arrow_forward4. Mancio Manufacturing Co. has asked you, as their IE, to check a labor standard prepared by a recently resigned analyst. Determine the sample size you need considering your accuracy is to be within 5%, standard deviation of the sample is 1.0 and the mean is 3.0. 5. The manager of Asombrado Bounty Office, Charles Badillo, estimates his employees are idle 25% of the time. With that problem, how many work samples are needed to consider within 3% accuracy and have 95.45% confidence level. 6. At ASP Micro Manufacturing, Inc. workers press semiconductor into predrilled slots on printed- circuit boards. Determine the normal time of the operation in seconds. The elemental motions for normal time used by the company are as follows: Reach 6 inches for semiconductors 10.5 TMU • Grasp the semiconductors • Move semiconductor to printed-circuit board 9.5 TMU • Position semiconductor 8.0 TMU 20.1 TMU Press semiconductor into slots 20.3 TMU Move board aside 15.8 TMU 7. The semiconductor used in…arrow_forwardEach year, Lord & Taylor, Ltd., sets up a gift-wrappingstation to assist its customers with holiday shopping. Preliminaryobservations of one worker at the sta tion produced the followingsample time (in minutes per package): 3.5, 3.2, 4. 1, 3.6, 3.9.Based on this small sample, what number of observations wouldbe necessa ry to determine the true cycle time with a 95% confidencelevel and an accuracy of ± 5%?arrow_forward

- How reliable is the result of work sampling activity in determining working time and idle time of the operator?arrow_forwardSupervisor Kenneth Peterson wants to detem1ine thepercentage of time a machine in his a rea is idle. He decides to usework sampling, and his initial estimate is that the machine is idle 20%of the time. How many observations should Peterson take to be 98%confident that the results will be Jess than 5% from the true results?arrow_forwardA time study in a manufacturing company of air conditioners showed the following results for the four basic elements of the production process. With the information presented in the table below: hat is the observed time for the whole operation? 00000 48.5 45.5 51.3 47.9 50.6 Elements B C D Rating Factor (%) 95 100 110 105 2 5 Observations (minutes) 4 2 3 3 12 11 13 15 21 23 18 14 8 6 12 7 5 3 9 6 7 4 4 2 12 21 23 8 6 8 23 10 19 4 10 12 13 10 5 14 29 12 23 15 12 8arrow_forward

- What would typically happen if an abnormally short time was recorded when conducting a stopwatch time study? a) It would be included in the study. b) It would be discarded. c) It would be factored by the performance rating. d) Inform the supervisor of the abnormality.arrow_forwardAn initial time study was done on a process with the following results (in minutes). Based on the data obtained so far, assuming an allowance of 20 percent of the normal time, what do you estimate for the time per customer served, based on this preliminary sample? Element Element 1 Element 2 Element 3 Performance Rating 70 110 90 Obs 1 4 8 6 Obs 2 3 10 8 Obs 3 5 9 7 Obs 4 4 11 7 Obs 5 3 10 6arrow_forwardWhat are the trade offs in choosing between time study and work sampling for work measurement.arrow_forward

- Determine the standard time of the process using the below-recorded observations. Hint: remove unusual time observationsarrow_forwardCompare stopwatch time study and work sampling.arrow_forward. Given the following information, determine the sample sizeneeded if the standard time estimate is to be within 5 percent ofthe true mean 97 percent of the time. Work Element Standard Deviation (minutes) Mean Observed Time (minutes)l 0.20 1.102 0.10 0.803 0.15 0.904 0.10 1.00arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.