Operations Management

13th Edition

ISBN: 9781259667473

Author: William J Stevenson

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

Chapter 14, Problem 6P

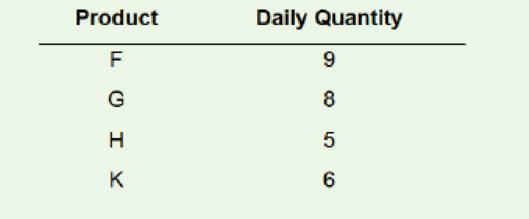

Determine the number of cycles per day and a production quantity per cycle for this set of products that achieves fairly level production:

Assume the production sequence will be F-G-H-K.

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

Suppose a final assembly is produced by assembling two components. THE The first component, A, is produced internally and goes through three process steps, which are stamping, forging and machining, with scrap estimates of 10%, 15% and 25%, respectively. For every three produced units of component A, two are used in the final assembly and one is separate to meet spare parts needs. The second component, B, which is used exclusively in final assembly, is purchased from a supplier external and inspected on arrival; 2% do not pass inspection. A unit of the component purchased is required for each final assembly. The final assembly process produces 5% of scraps. Spare parts demands for component A and final Su assembly match to 1,000 and 5,000 units, respectively. How many input units are needed for produce component A, and how many units of component B should the firm buy?

Atlanta Manufacturing Company produces products W, X, Y, and Z through a joint

process. The joint costs amount to $250,000.

Product

Units

Produced

Sales Value

at Split-Off

Additional Costs

of Processing

Sales Value

After Processing

W

750

$10,000

$2,500

$15,000

X

1,500

$30,000

$3,000

$35,000

Y

1,000

$20,000

$4,000

$25,000

Z

1,500

$40,000

$6,000

$45,000

If W is processed further, profits of W will:

1) Increase by $2,500

2) Increase by $12,500

3) Decrease by $23,000

4) Increase by $5,000

A Company belonging to the process industry carries out three consecutive processes. The output of

the first Process is taken as input of the second process, and the output of the second process is taken

as input of the Third process. The final product emerges out of the third process. It is also possible to

outsource the intermediate Products. It has been found that over a period of time cost of production

of the first process is 10% higher than The market price of the intermediate product, available freely in

the market. The company has decided to close

Down the first process as a measure of cost saving (vertical spin off) and outsource. Should this event

be treated

As discontinuing operation?

Chapter 14 Solutions

Operations Management

Ch. 14.S - Prob. 1DRQCh. 14.S - Prob. 2DRQCh. 14.S - Prob. 3DRQCh. 14.S - Prob. 4DRQCh. 14.S - Prob. 5DRQCh. 14.S - Prob. 6DRQCh. 14.S - Prob. 7DRQCh. 14.S - Prob. 8DRQCh. 14.S - Prob. 9DRQCh. 14.S - Prob. 10DRQ

Ch. 14.S - The probability that equipment used in a hospital...Ch. 14.S - The frequency of breakdown of a machine that...Ch. 14.S - Prob. 3PCh. 14 - Prob. 1DRQCh. 14 - Prob. 2DRQCh. 14 - Prob. 3DRQCh. 14 - Prob. 4DRQCh. 14 - Prob. 5DRQCh. 14 - Prob. 6DRQCh. 14 - Prob. 7DRQCh. 14 - Contrast push and pull methods ofmovi.ttg goods...Ch. 14 - Prob. 9DRQCh. 14 - Prob. 10DRQCh. 14 - Prob. 1TSCh. 14 - Prob. 2TSCh. 14 - Prob. 3TSCh. 14 - Prob. 1CTECh. 14 - Prob. 2CTECh. 14 - Prob. 1PCh. 14 - Prob. 2PCh. 14 - Prob. 3PCh. 14 - Determine the number of cycles per day and the...Ch. 14 - Given this set of daily service operations, and...Ch. 14 - Determine the number of cycles per day and a...Ch. 14 - Compute the takt time for a system where the total...Ch. 14 - Prob. 8PCh. 14 - Prob. 9PCh. 14 - What might Stephanie determine as the best...

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- The Chineke Group of Company manufactures two products, namely product B and product P, and provides you with the following information: Prod. B Prod. P Selling price per unit 80.00 50.00 Less cost of sales: Direct material A @ R5.00 per kg 15.00 10.00 Direct material B @ R4.00 per kg 8.00 12.00 Direct labour @ R6.00 per hour 12.00 6.00 Variable manufacturing overhead @ R5.00 per labour hour 10.00 5.00 Fixed manufacturing overhead per unit 5.00 5.00 Gross profit 30.00 12.00 Less sales & administrative costs: Variable 6.00 4.00 Fixed 10.00 5.00 Net profit per unit 14.00 3.00 Take note of the following constraints: Material A available 360 kg Material B available 360 kg Labour hours available…arrow_forwardA bicycle component manufacturer produces hubs for bike wheels. Two processes are possible for manufacturing, and the parameters of each process are as follows: Process 1 Production rate Daily production time Process 2 35 parts/hour 4 hours/day 20% 15 parts/hour 7 hours/day 9% Percent parts rejected Assume that the daily demand for hubs allows all defect-free hubs to be sold. Select the process that maximizes profit per day if each part is made from $4 worth of material and can be sold for $30. Both processes are fully automated, and variable overhead cost is charged at the rate of $40 per hour.arrow_forward#4- The mean number of air conditioning units assembled per month by Freeze, Inc. is 750 and the standard deviation is 100 units. a. If the number of air conditioning units assembled per month follows a normal distribution, calculate the probability of Freeze, Inc to assemble a quantity of air conditioning units greater than the monthly break-even point calculated in problem 3-a. b. An improved assembling process is proposed to Freeze, Inc. to reduce the variable cost from $500 per unit to $400 per unit., increase the mean number of air conditioning units assembled per month from 750 to 850 and reduce the standard deviation to 90 units. As a result of the improvements, monthly fixed costs would go up from $250,000 to $300,000. Once these improvements are implemented, calculate the new number of air conditioning units that Freeze Inc. must sell every month to break-even, discuss and justify if you would recommend the process improvement initiative. c. If the number of air conditioning…arrow_forward

- 2) BAQARAH Milk is fresh cow’s milk from Bangladesh’s first industrial hi-tech dairy farm which is equipped with the most advanced technology for milking cows and processing milk. All the cows are purebred Holstein Friesian from Australia. The farm ensures that milk is hygienically produced without human touch from milking to packing. It is instantly pasteurized to preserve the milk quality. The key features of BAQARAH milk is pure, fresh, low fat, free of antibiotic, free of toxin and of global standard. a) Which pricing strategy will be applicable for this product- price skimming or pricing penetration? Justify your position with three proper logics. b) In the given situation, which stage of buying decision process of consumers the company is trying to influence and how?arrow_forwardPepsi and Coca-Cola typically utilize which of the following production strategies for their sodas? Group of answer choices a Back Office b Assembly Line c Make-to-stock d Make-to-order e Continuous flowarrow_forward15-15 Kitty Products caters to the growing market for cat supplies, with a full line of products, ranging from litter to toys to flea powder. One of its newer products, a tube of fluid that prevents hair balls in long-haired cats, is produced by an automated machine that is set to fill each tube with 63.5 grams of paste. To keep this filling process under control, four tubes are pulled randomly from the assembly line every 4 hours. After several days, the data shown in the following table resulted. SN = Sample number SN x¯ R1 63.5 2.02 63.6 1.03 63.7 1.74 63.9 0.95 63.4 1.26 63.0 1.67 63.2 1.88 63.3 1.39 63.7 1.610 63.5 1.311 63.3 1.812 63.2 1.013 63.6 1.814 63.3 1.515 63.4 1.716 63.4 1.417 63.5 1.118 63.6 1.819 63.8 1.320 63.5 1.621 63.9 1.022 63.2 1.823 63.3 1.724 64.0 2.025 63.4 1.5 Set control limits for this process and graph…arrow_forward

- Can you do the calculations in Excel file showing all the work? You are a planner at a small distribution warehouse. Historically, the warehouse has targeted fulfilling 10 orders per hour for planning purposes. However, as the diversity of products has expanded, as well as the size of orders, this target has proven to be unreliable, as the orders are continually behind schedule and customers are complaining about late deliveries. Your supervisor has tasked you with determining a better target so that the warehouse may provide better delivery estimates to customers for their orders. Over the past week you gathered data for the number of orders fulfilled each day. This data is shown in the following table. Day Monday Tuesday Wednesday Thursday Friday Orders 88 64 72 56 80 A. Assuming 8 hours of operations each day, what is the mean and standard deviation for orders fulfilled per hour? The following table may help with these calculations. N is the total…arrow_forwardDoes the process optimise the desired demand of the customer?arrow_forwardAssume that Product Z is made of two units of A and four units of B. A is made of three units of C and four of D. D is made of two units of E. B is made of three units of E. If 50 units of Z is required to make, then how many units of D do they need? Group of answer choices 250 400 300 150 550arrow_forward

- What is the definition of a processing item?arrow_forwardWhen selecting date units for grouping, users can select multiple units of measure. True Falsearrow_forwardThe sales department receives all orders from the customers. While receiving the order, the sales team authorizes the payment and check line items. If authorization is failed, a cancelation message is sent to the customer. On the other hand, each line item is checked with the stock. If it is in stock, assigned to the order otherwise the item is removed from the list. If stocks are available for all products and payment is authorized, the sales team dispatched the order.Shipping teams ship the order to the customer. The method of delivery is decided conditionally. Depending on the condition either the Urgent Delivery activity or the Regular Delivery activity is performed. The delivery procedure is finished when the customer receives it and signs in. Draw an Activity diagram based on the above scenario.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.

Inventory Management | Concepts, Examples and Solved Problems; Author: Dr. Bharatendra Rai;https://www.youtube.com/watch?v=2n9NLZTIlz8;License: Standard YouTube License, CC-BY