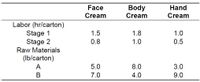

Face Body Cream Hand Cream Cream Labor (hr/carton) Stage 1 Stage 2 1.5 1.8 1.0 0.8 1.0 0.5 Raw Materials (Ib/carton) A 5.0 8.0 3.0 В 7.0 4.0 9.0

Oh no! Our experts couldn't answer your question.

Don't worry! We won't leave you hanging. Plus, we're giving you back one question for the inconvenience.

Briley Cosmetics Inc.

Briley Cosmetics manufactures and distributes a wide range of skin care products. A recent order has arrived for 10,000 cartons of face cream, 5,000 cases of body cream, and 15,000 cases of hand cream. The manufacturing process consists of a two-stage procedure that uses two types of raw materials (A and B). Briley’s monthly production capacity (first shift) is 15,000 labor-hours for stage 1 and 10,000 for stage 2. The first shift hourly rates are $8.50 for stage 1 and $9.25 for stage 2. A second shift is available with a 10% reduction in capacity and a 10% increase in wage rates. The cost for raw materials is $1/pound for Type A and $1.50/pound for Type B. The manufacturing facility has available for the next production run 200,000 pounds of Type A and 150,000 pound of Type B. The following table summarizes the resource requirements to produce each product

Briley can also subcontract with a local supplier for face cream and body cream at a cost of $40/carton and $55/carton, respectively.

1. What production schedule minimizes total cost while meeting product demand?

2. How much face cream and body cream is subcontracted out?

3. What is the value of the objective function?

4. Which labor and material resources are completely used?

5. What would be the impact on the optimal solution if the demand for all three products were decreased by 10% each?

6. What would be the impact on the optimal solution if hand cream could be subcontracted at a cost of $35/carton?

**required chart is saved as the image below